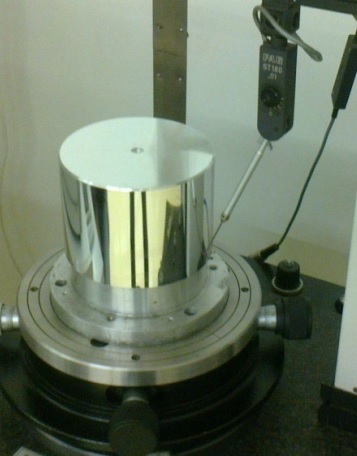

Ultraprecision lathe

SCOPE OF APPLICATION

All those fields in parts manufacturing where the geometrical size tolerances and the surface roughness should be specified close to the values given in the above tables. By means of the high-precision machining operations described further below the dimensional stability can be realized and kept under control more favourably than with abrasive grinding technologies.

With respect to turning the expectable scope of users can be the following:

Among the manufacturers of high-precision metal parts. Characteristically, these are users coming from the special-purpose machine industry. This is a noteworthy group of users where the grinding of hardened parts should be replaced in order to reduce production time. Also, the more precise shaping of the basis surfaces on higher-accuracy parts might be important. It could also prove to be a remarkable technological solution for the manufacturers of some microelectronic parts, as well as hydraulic and pneumatic parts in producing finely-fit finished parts.

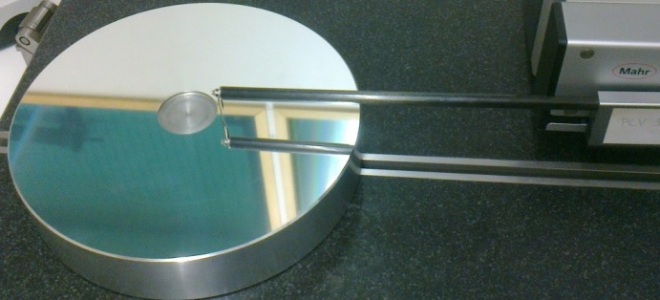

Further users could be firms intending to process non-metallic materials such as special lenses’ makers e.g. in optical industry, producers of solar station elements fitted with so-called flat-mirror or parabolic mirror for direct utilization of solar energy. Also to the scope of users belong the companies producing individual elements for nuclear power plants and firms manufacturing special devices for the armaments industry.