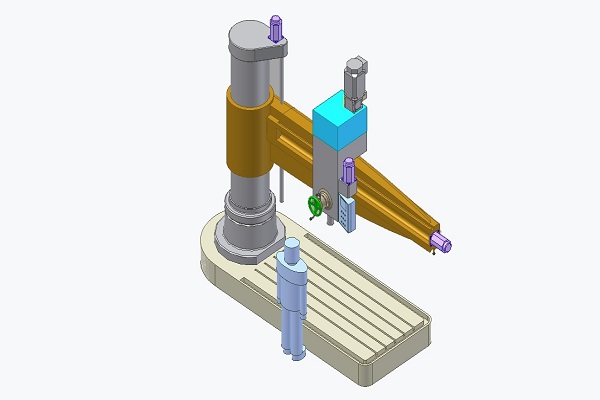

Reconditioning of radial drilling

Excel Csepel Kft offers a solution for the overall modernisation and betterment of radial drilling machines of various types.

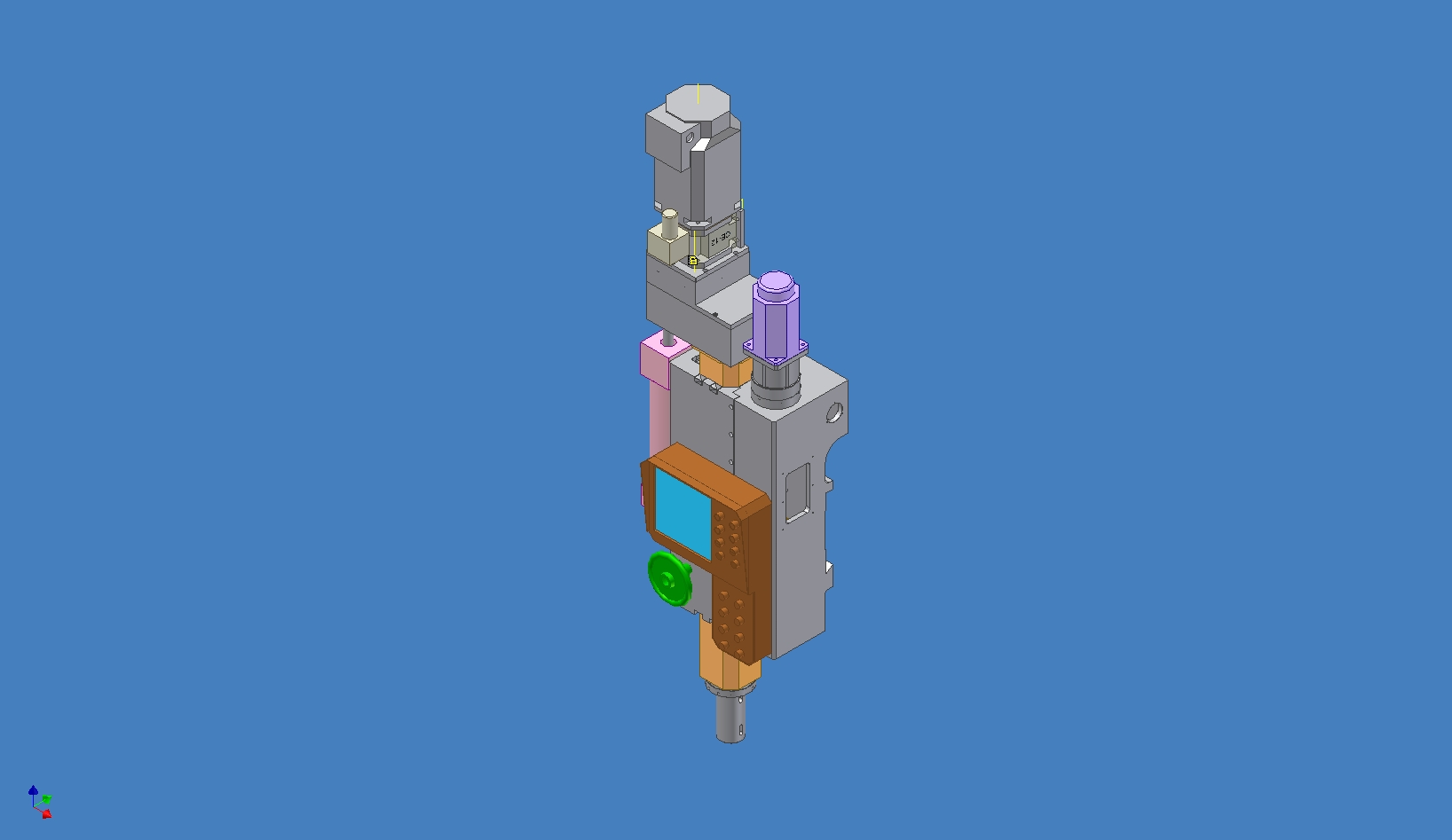

This includes the replacement of the spindle headstock by an axis-controlled unit that complies with the requirements of our time resulting in the machine being fitted with functions and parameters in Z-sense position that are characteristic for NC machines.

The radial drilling machine RFH-100 has a slide system and a drilling spindle with Micromat control. Besides the control unit the control panel accomodates the different control elements as well. In modernizing the machine we kept all the routine and accustomed functions that are comfortable for the machine operator.

Simultaneously we implemented functions rendering possible for the operator to run various machining cycles while these cycles include all necessary information and data required for the machining of different holes.

These data are stored in the memory of the control. The system can manage altogether 99 cycles which can be modified, copied and triggered according to the operator’s wish.The 27,75-kW main drive is connected to a two-stage back-gear Baruffaldi CE13 with 1:1 and 1:5 gear ratio. Torque is transmitted via belt-drive with a gear ratio of 1:1. Drive to the spindle is via gearing with a gear ratio of 1:2.

Drilling spindle movement is effected by means of a parametrizable NCT drive. The rated torque of this drive is 50Nm which renders possible to maintain all machine parameters. The parameters of the individual cycles can be called for modification, and information can be gained on all in- and output data. Detection of a position in Z-axis is effected with the aid of Heidenhain encoders.

You keep the original drilling machine structure, and we’ll give you a brand-new drilling spindle headstock along with an all-in modernized machine!