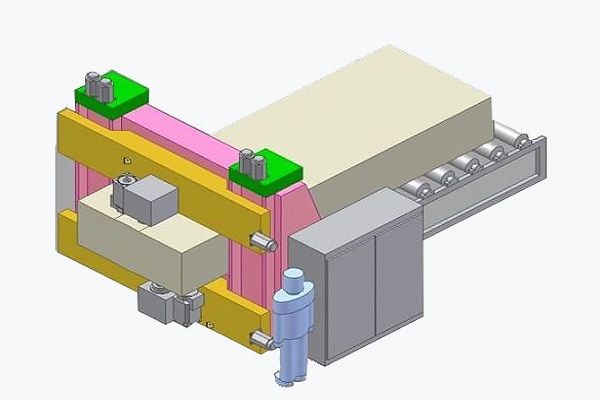

Roll forming mill for machining of billets

The ingots placed on the roller are machined simultaniously on both the upper and bottom side at the same time. The machine has a 22kW main drive, which drives a 200mm diameter milling cutter. The milling tool was moved in transversely and vertically with servo axes. The longitudinal displacement is carried out using the existing driven rollers. The protrusion can be cut off with more than one spin. This machining center with frame construction is controlled by a Fanuc controller. Moving the sleighs with 22 Nm servomotors is performed by means of a ball spool. The guide system of the sleighs is a linear guide rail.