Over speeding

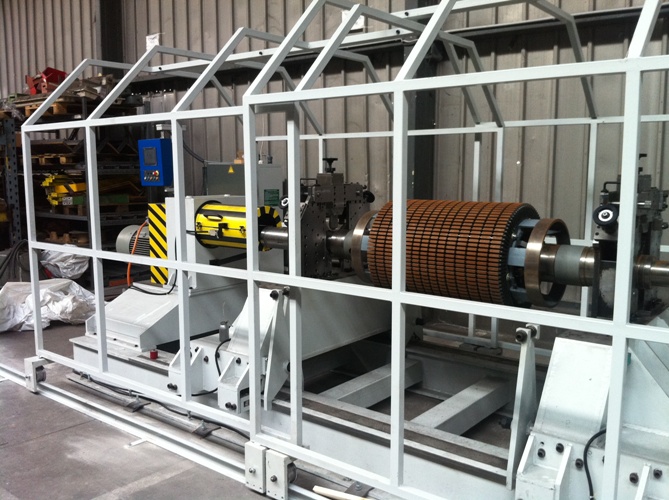

Automated control of assembled, bandaged, vacuum impregnated electric rotor with overdrive at + 25% increase in nominal speed.

When designing the machine, the largest dimension of the workpiece, currently 4000mm long, 950mm in diameter, and the corresponding weight reaches 4500kg. In case of over-rolling vibrations that are higher than allowed, the process should be stopped to avoid further damage to the rotor and avoid the risk of spin-off.

Operation

Positioning the workpiece by crane is performed on the slots fitted according to the bearing positions. Safety fastening with straps placed on the latches, when an error message is displayed on the screen, an error message appears on the display, the process can not be started. Spin is achieved by rotor drive shaft with a frequency inverter. The value of the vibration generated by the spin, the duration of the rotation, the completion of the task and the additional data, is displayed on an external server. After proper rotation, the rotational energy, as braking energy is recycled to the grid.

Security conditions:

Placement of the equipment in a specially designed room. The value of the imbalance is continuously monitored during the run-up and running of the speed, in case of anomalies the process is stopped automatically.

Az összeszerelt, bandázsolt, vákumimpregnált elektromos forgórész automatizált ellenőrzése túlpörgetéssel, a névleges fordulatszám +25%-ával növelt fordulaton.

Technical parameters click here