EGP 32/100NC mantel grinder

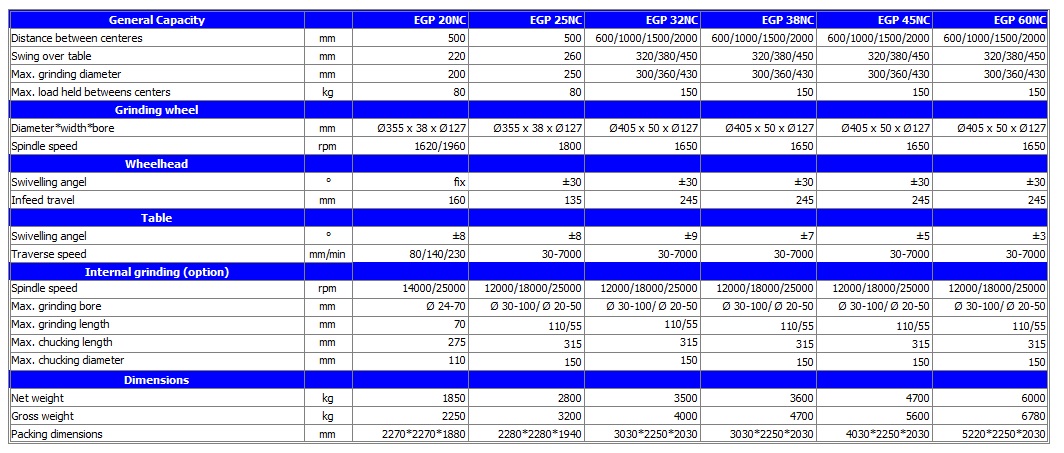

The EPG mantle grinder family includes a wide range of manually handled M / H models and auto-gripping NC models. The EPG series is widely available with a 200/250/320/450 mm turning diameter and a grinding length between 500/600/1000/1500/2000 mm. The grinding option can be extended with a bore grinder unit.

All models have a machine bed with a so called Meehanite box structure with hydrostatic conduit system, variable speed workpiece spindle, separate hydraulic system. EPG32 and larger models are 7.5 HP (hp) equipped with a spindle motor that has iut’s own cartridge type automatic spraying system for improved grinding performance.

The NC models feature easy-to-use, touch-screen LCD display with operator interface control. It is sufficient for the operator to choose the right grinding cycles by setting the appropriate parameters. Optionally available with an automatic stone conveyor unit and a grafting function to compensate for the stone diameter change the grinding time can be significantly reduced and a more favorable surface quality is achieved.

BASIC ACCESSORIES

- Stone Balancing Unit

- Rock balancing shaft (spindle)

- Stone insertion unit

- With grinding wheel grasping unit

- Toolbox with tools - with tools for adjustment

- Stone sharpener - mounted on a table

- Machine book with bills of exchange

- Measuring clock

- Partial splash protection

- cooling System

- Hard metal driveway edge

- Fixing clamps

- Work lamp

- Grinding stone

- Chuck with 3 jaws, catching board

- Cartridge mdb. holders D4-D20mm with 17pcs cartridges

- Back-rest (2) opposing surfaces

- Magnetic Oil Filter (60L / min, 140L)

- 2 stone hőlder wheels

- Bore grinding head - accessory for EGP32 machine type (25000 rpm)

- D30 - D100mm, L110mm

- D25 - D55mm, L55mm

OPTIONS

- Bore grinding head - accessory for EGP20 machine type (12000, 18000, 25000 rpm)

- Bore grinding head - additional unit for EGP32 machine type (12000, 18000, 25000 rpm)

- D30 - D100mm, L110mm

- D25 - D55mm, L55mm

- Back-rest (2) opposing surfaces

- Stone scraper –to create radius

- Stone scraper –to create cone

- Stone scraper –micro design

- Roller Static Stone Balancing Unit

- Overhead - scraper unit - with automatic stone diameter compensation

- Overhead – scraper unit - for parallel upgrading of side surface

- Cooling unit

- Centrifugal separator - for oil cooler cleaning

- Automatic workpiece measuring unit

- Digital measurement display

- Reserve grinding wheel

- Reserve stone fixer

- Hydraulic saddle stitch

- Dynamic stone balancing unit

- Cooling oil cleaning unit with magnetic separator and paper filter

- Spindle, stone speed control

Technical parameters click here

Additional machine types