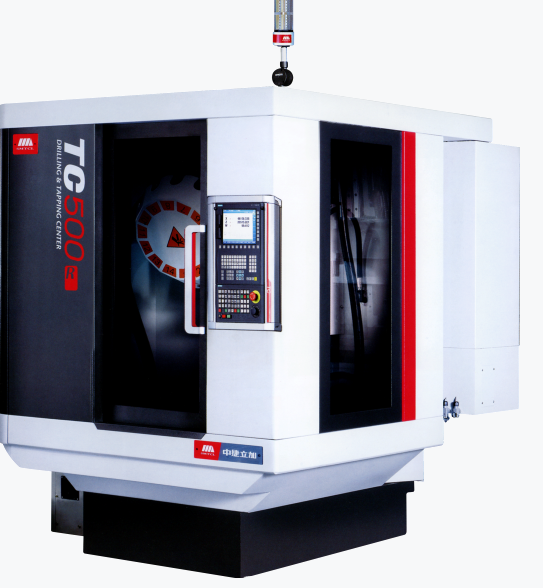

TC500R drilling&tapping center

TC500R high speed drilling & tapping center can perform the machining of drilling, tapping, and milling and smooth curve process with high speed, high accuracy and high efficiency. TC500R vertical drilling & tapping center adopts vertical frame layout, the column is fixed to the bed, the spindle box moves up and down along the column (Z direction), the slide carriage moves longitudinally along the bed (Y direction), and the table moves horizontally along the slide carriage (X direction).

Standard configuration

- Fanuc Oi Mate MD system

- 10000 rpm Spindle

- Turret-type tool magazine with 14 pockets

- Illuminating lamps

- Spindle taper hole cleansing air

- Cooling system

- 8,4” display

- Machine tool iron gaskets and adjustment bolts

- Technical dokumentation

- Aumatic centralized lubrication system

- Full enclosed workspace

- Three-color warning light

- RS232 interface

- Chi removal slot

- Spindle taper BT30 7/24

- Electric cabinet heat exchanger

Technical parameters click here